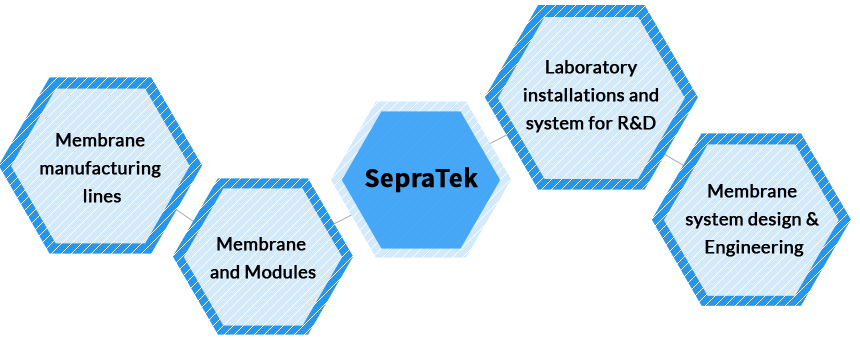

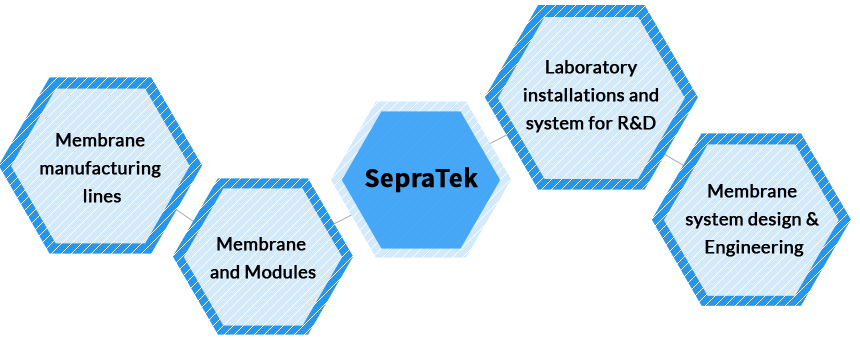

Business

SepraTek staffs have accumulated a wealth of experiences about how to fabricate membrane and module, how to design membrane system, and how to optimize membrane process. Based on the experiential expertise, we are working on the following areas;

Hollow fiber membranes and modules

-

Membranes for pervaporation of high temperature and/or high pressure application

-

Membranes for vapor permeation for recovery of valuable VOCs from discharge stream in petroleum and chemical processes

-

PP hydrophobic porous membrane for membrane contactor for separation of CO2 from gas mixtures, degassing and gassing process

-

MF membranes for waste water treatment and water purification

Membrane process and system design

-

Pervaporation: dehydration process and VOC-selective process

-

Vapor permeation: VOC recovery in petroleum and chemical process

-

Membrane contactor for separation of CO2 from gas mixtures, degassing and gassing process

-

Gassing and degassing membrane processes

Membrane manufacturing lines

-

Hollow fiber membranes, flat sheet membranes by DIPS (Diffusion Induced Phase Separation) or TIPS (Thermal Induced Phase Separation)

-

Lab-scaled, and commercial scaled production lines

Installations and systems for R&D

-

Lab-scaled and pilot-scaled membrane system

-

Permeation Membrane Analyzers

-

Laboratory installation for R&D works