TIPS

SepraTek has established the innovated TIPS (Thermally Induced Phase Separation) process which enables to produce a large diameter of chemically stable porous hollow fiber membranes without stretching process.

The TIPS process can not produce hollow fiber membranes having a wide range of porosities as well as various diameters but also produce a robust hollow fiber reinforced by a braid. The process can diversify membrane material up to chemically-stable polymers which can not be shaped by the DIPS process.

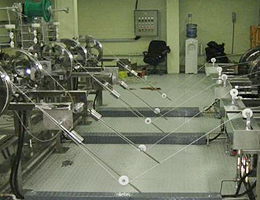

The offered manufacturing line for hollow fiber membrane is designed and built of a practical value, based on a wealth of experiences of SepraTek engineers acquired from field works for a long period of time.

The manufacturing unit involves valuable SepraTek’s proprietary technologies, including the design of twin-screw extruder, the methodologies of feeding of respective stream into the extruder, the design of piping from discharge port to spinning nozzle, spinning mode to secure a perfect shape of spun hollow fiber and porous structure at the outer surface of hollow fiber, and so on, being really the embodiment of our many year’s R&D efforts. The manufacturing system is briefly described as ;

- No stretching process needed to form highly porous structure

- Diverse spinning nozzles designed by SepraTek proprietary technology to be able to maintain the uniform temperature distribution of dope flow in the nozzle

- Controlling of the temperatures of nozzle and two streams (bore liquid and dope solution) into nozzle, respectively

- Being able to produce a wide range of porosities as well as various hollow fiber diameters

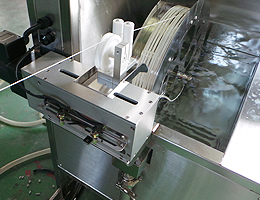

- Precise control system on pulling and winding of hollow fiber membrane

- Continuous manufacturing process in which each raw materials feed continuously into the manufacturing unit to produce hollow fiber membrane

- Easy operation and easy maintenance

We supply a batch type of TIPS spinning unit in which an autoclave is employed to prepare a dope solution at elevated temperature instead of the twin-screw extruder.

We also offer consulting service as well as membrane-manufacturing technologies as optional The following membranes can be manufactured by the line:

- Microfiltration/Ultrafiltration

- Nanofiltration/Reverse Osmosis

- Pervaporation/Vapor Permeation

- Gas Separation

DIPS

he offered manufacturing line for hollow fiber membrane is designed and built of a practical value, based on a wealth of experiences of SepraTek engineers acquired from field works for a long period of time.

Basically, hollow fiber membrane is formed by DIPS (Diffusion Induced Phase Separation) mechanism in the line, and a variety of dimensional specifications of hollow fiber membrane, such as, inner diameter and thickness of hollow fiber membrane can be manufactured in precisely control.

Also, customized designs are available to meet client’s specific demands. The manufacturing system is briefly described as ;

- Easily adjustable air-gap

- Spinning nozzles designed by SepraTek proprietary technology to be able to form a perfect shape of hollow fiber.

- Controlling of the temperatures of nozzle and two streams (bore liquid and dope solution) into nozzle, respectively

- Precise control system on pulling and winding of hollow fiber membrane

- Adjustable spinning speed

- Easy operation and easy maintenance

We supply membrane fabrication unit for R&D use to develop membrane, which is specifically designed to quickly and precisely come out a response corresponding to a change of a input parameter.

We also offer consulting service as well as membrane-manufacturing technologies as optional, and supply peripheral equipments, such as, module potting machines, Injector of potting resin, module cutting machines, and spinning nozzles. The following membranes can be manufactured by the line:

- Microfiltration/Ultrafiltration

- Nanofiltration/Reverse Osmosis

- Pervaporation/Vapor Permeation

- Gas Separation