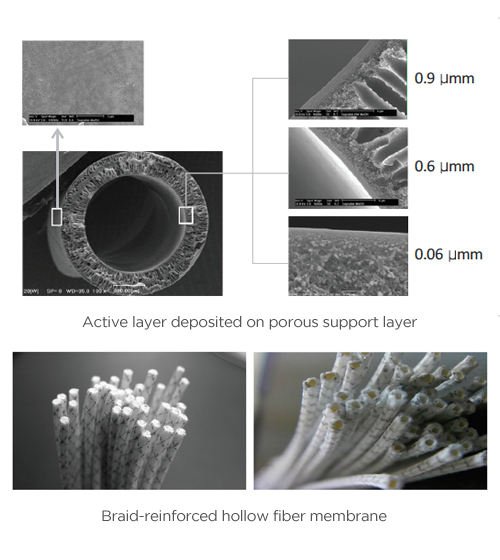

The novel technologies of SepraTek make it possible to fabricate a hollow fiber form of pervaporation composite membranes, utilizing the significant benefits of hollow fiber membrane shape; high membrane packing density in module, low fabrication cost, flexibility in membrane module design and so on.

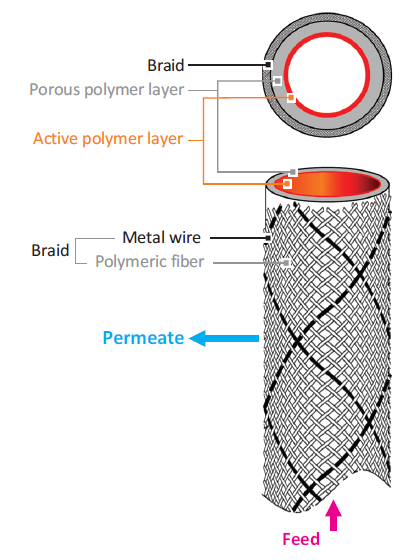

The benefits of the hollow fiber membrane will spread its application widely. SepraTek™ hollow fiber composite membranes have a braid fabric structure of reinforcement, a porous layer and an active layer.

The braid fabrics are fabricated by braiding polymeric fibers and metal wires together, so SepraTek™ hollow fiber composite membranes reinforced by the braid possess an excellent pressure-resistance as well as a good dimensional stability in organic solvents even at high temperature.