As in the pervaporation membrane, SepraTek™ hollow fiber composite membranes for vapor permeation process are installed in standard hollow fiber modules housed in pressure vessels which contain a VOCs/gas mixture. They are basically designed for high pressure processing of VOCs/gas mixture.

Non-braided hollow fiber membranes also are available for low pressure application. Especially, SepraTek possesses diverse membrane module fabrication techniques including potting resin formulation, potting art and module design.

Membrane modules which are very stable even in aggressive organic solvent at high pressure can be fabricated by an established methodology. A membrane system is designed and engineered through systematical simulation and a sequence of groundworks so as to maximize membrane performance as well as the economical value of the membrane process.

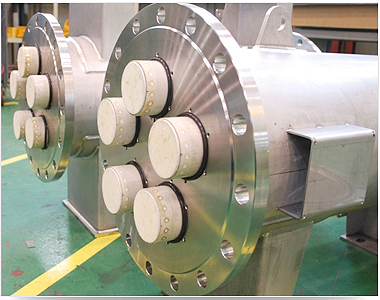

- Membrane module and assembly

- In the process, feed flows along with the inside of respective hollow fiber membrane loaded in membrane module. The structural designs of membrane modules for vapor permeation are exactly identical with those for pervaporation. In order to simplify piping and to apply vacuum effectively to the permeate side of membrane module, a number of unit modules are packed into a body, called “module assembly” in fabricating a large scale of vapor permeation system. The number of unit modules can be determined, depending on the hydraulic characteristics of feed, the scale of vapor permeation system, separation extent to be achieved, and so on.

- Scope of supply

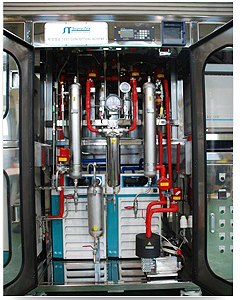

- SepraTek can design and supply complete separation systems based on vapor permeation with or without cryogenic condensation steps. SepraTek supplies completely preassembled units as well as (basic) engineering with components.

- SepraTek™ vapor permeation system features

- flexible process : a single unit can be designed to treat a large number of solvents

- both on and off-site piloting available

- standard skid mounted units for fast delivery and installation and minimum hook-up time

- compact and easily scalable

- Low capital cost and operation cost in compared with other competitive processes

- very short payback time