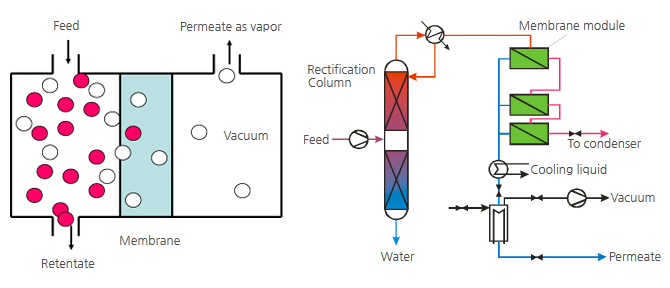

Pervaporation is a membrane process for separating liquid/liquid mixture. The application is classified into three categories as follows;

-

Dehydration of organics

-

Removal of VOCs from aqueous organic solution

-

Separation of organic/organic mixtures

Especially, the dehydration of organic liquid is a major application. Pervaporation enables solvents to be dehydrated without using any third substance or entrainer. Azeotropes can be dehydrated simply, cheaply and without problems irrespective of vapor/liquid equilibria. Similar to water, methanol can be removed out of organic solvents.

-

Pervaporation Membranes

-

In pervaporation, composite membranes which have a fabric structure of reinforcement, a porous layer and an active layer on the top of membrane are used. As a rule of thumb, an active hydrophilic separating layer is employed for preferentially permeating the water, while a hydrophobic or organophilic material is used as an active layer for preferentially permeating the VOCs. The crosslinking of the active layer determines the behavior of the membrane regarding permeate flux, selectivity and chemical resistance. The crosslinking of this layer determines the behavior of the membrane regarding permeate flux, selectivity and chemical resistance.

-

Pervaporation Features

-

tailored non-porous membranes which selectively absorb and permeate a specific component

-

driving force from vacuum applied to back side of the membranes, allowing almost complete removal of the permeating component

-

permeating component leaves membrane as a vapor

-

separation predominantly by polarity difference - polar compounds permeate faster through hydrophilic membranes

-

feed can be liquid (pervaporation) or saturated vapor (vapor permeation)